Stationary Powder Filling Unit

AMK-500 TRIO · No. 165 000

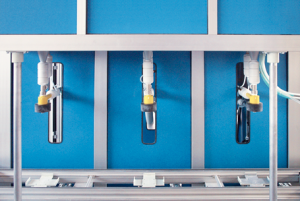

SPS-controlled fire extinguisher filling plant AMK-500 TRIO – belt system facilitates the filling techniques reliable and precise.

The automatic EMDE – SPS-controlled fire extinguisher filling plant AMK-500 TRIO – belt system and the Siemens-SPS-control with EMDE-software guarantee a high operational reliability in the filling of fire extinguishers.

The compact construction of the AMK-500 TRIO demands a low space requirement in the production plant. The working stations of filling, processing and final completion of the fire extinguisher are coordinated with the production process to secure the quality standards as well as the productivity. All components are manufactured according to the standards for unitries and convince by its safety standards beyond the requested standards.

| TECHNICAL DATA |

|---|

| Dimensions (l x w x h) | approx. 2000 x 2200 x 4000 mm |

| Construction | aluminium |

| Motor | three-phase current 230/400 V, 50 Hz, 32 A |

| Compressed-air | 8 – 10 bar, 1000 – 1500 l/min |

| SPS-control | Siemens |

| Filter-system | self-cleaning, maintenance-free |

| Vacuum pump | rotary vane vacuum pumps air-cooled, 63 m3/h |

| Scale | 3 x 60 kg, 10 g resolution |

| Colour | hammer finish painted blue |

Operation of the AMK-500 TRIO guided by menue, compact and easy to survey by Siemens-Touch PC.

- absolute dustless filling procedure

- modular construction enables variable extension according to customer concern

- control of the complete procedure by sensor technology

- large fire fighting appliances can be filled by additional adaptor outside of the unit

- three disjoined filling positions

- variable height adjustment of filling head driven by spindle in case of change of fire extinguisher model

- three integrated filter tanks with automatic filter cleaning

- three universal filling heads appropriate for all fire extinguisher openings

- automatic dosing for 1 – 12 kg with control weighing

- filling and final completion with three workmen

- powder filling capacity: approx. 1500 pcs. per day à 8 hours according to powder quality*

* Theoretically calculated numerical value for powder filling without moving and handling time.

Advantages at one sight:

- own research and development

- job-oriented production according to customers requirements

- latest technology

- Eextensive and optimal provision of services

- highest cost-effectiveness

The way to economy and precision is achieved by the EMDE – SPS-controlled AMK-500 TRIO fire extinguisher filling plant.